Strong Attendance at Inaugural Gulf Print & Pack in Riyadh …

The inaugural edition of Gulf Print & Pack Saudi Arabia, the Middle East’s leading commercial print and packaging trade show, held recently at Riyadh Front Exhibition Conference Center (RFECC), marked a significant milestone for the Kingdom's printing and packaging industry, bringing together more than 5,052 visitors from 54 countries.

The exhibition featured over 150 leading exhibitors and thousands of industry professionals from Saudi Arabia, UAE, Egypt, Kuwait, Qatar, China, Bahrain, Jordan, India, and Germany.

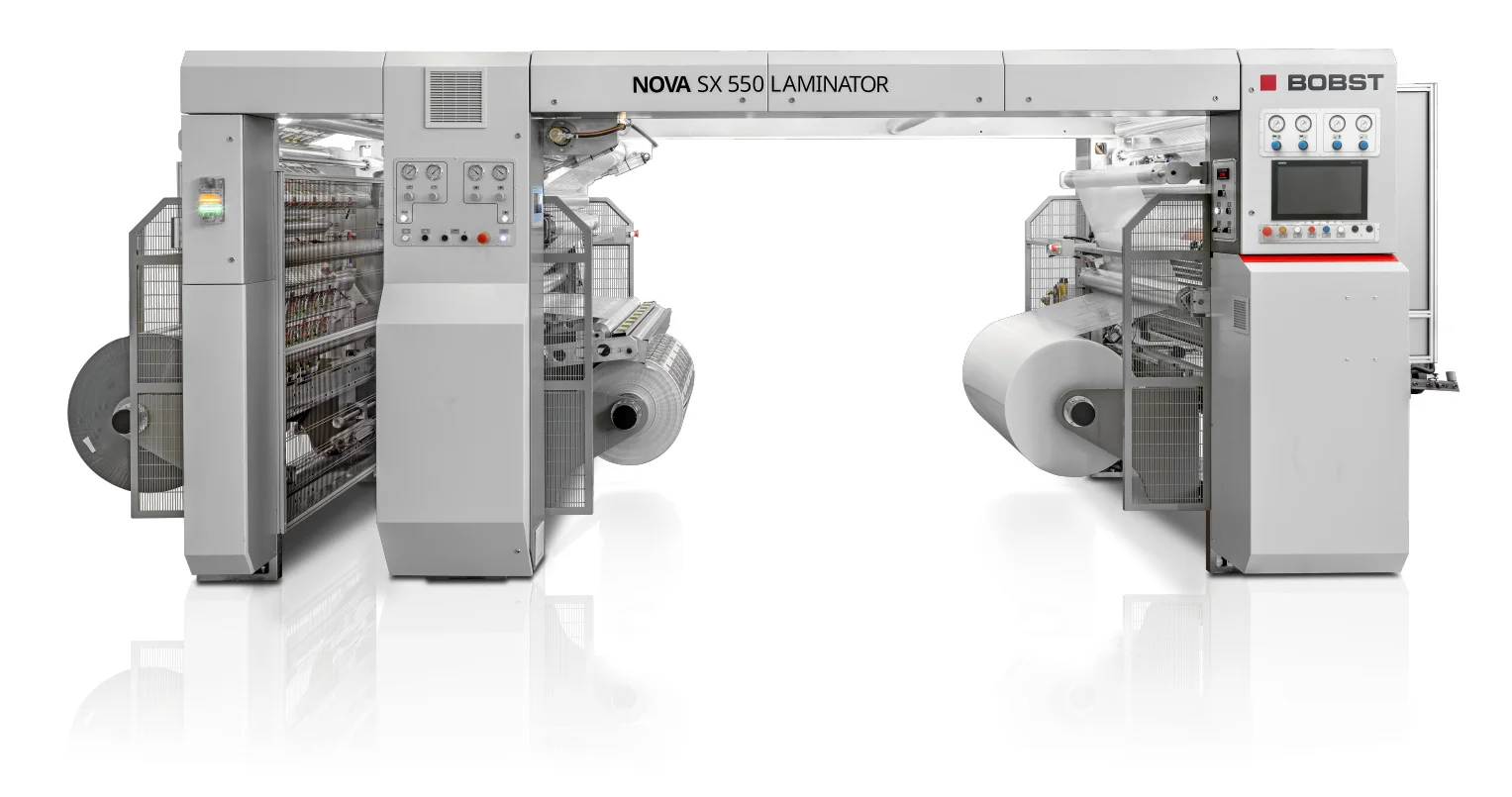

Gulf Print & Pack 2025 in Riyadh provided a tailored platform for the latest advancements in printing and packaging technologies. From high-speed digital presses and advanced packaging solutions to AI-powered workflow streamlining tools, the event provided a comprehensive overview of the industry's future direction. Major industry players, including Konica Minolta, BOBST, Ricoh, NDIGITEC, Canon, and Fujifilm participated in the event, highlighting their commitment to the Saudi Arabian market and the region's growing print and packaging sector.

“We are overwhelmed by the response to the inaugural edition of Gulf Print & Pack in Saudi Arabia. The attendance and participation from leading industry players is a testament to the potential of, and confidence in, the Saudi Arabian printing and packaging sector. There are encouraging signs for this platform in the Kingdom for major brands to showcase cutting-edge technologies, foster valuable connections, and drive the industry forward.” said Barry Killengrey, Event Director, Gulf Print & Pack.

Ricoh showcased its latest innovations and technology, highlighting how its solutions, including enhanced automation, can help improve business efficiency and reduce total cost of ownership. Ricoh's exhibit featured a range of digital printing systems, including the Pro 8400 digital mono sheetfed press, Pro C7500 digital color sheetfed press, Pro C9500 digital color sheetfed press, and Pro C5300 digital color sheetfed press, along with the Ricoh Auto Color Adjuster, cementing its expertise in multiple verticals, including luxury packaging.

Saudi-based Alkhorayef Printing Solutions, in collaboration with MTEX NS, showcased cutting-edge digital printing and packaging solutions including machines such as NS MULTI 1300, NS MULTI 80, NS AQUAFLEX S. Alkhorayef Printing Solutions brought advanced, sustainable technology directly to Saudi industries, empowering businesses with precision, efficiency, and innovative solutions for flexible and rigid packaging, commercial printing, and labels.

Ahmed Samy Eltantawy, Senior Sales Director, at Alkhorayef, said: “It was an exciting event for us to attend, providing us with a great platform to showcase our latest technologies to serve the regional sector.”

Konica Minolta covered three segments of Digital Production Print at Gulf Print and Pack 2025 with state-of-the-art AccurioPress C 14000, AccurioPress C 7100 and AccurioPress C 4080. Digital Embellishment was covered by AccurioShine 3600, Digital Spot UV with inline Single Pass Foiling system for decorative prints.

Fujifilm, a key exhibitor and industry leader, chose Gulf Print & Pack 2025 to launch two new mid-range printers. The company introduced a fifth colour option to their entry-level printer, the Revoria SC285s, and unveiled the EC2100, a mid-range workhorse printer featuring an entirely new platform and technology, promising significant technical advantages to customers.

Elsewhere Canon, the headline sponsor of the event, showcased a suite of cutting-edge digital printing solutions aligned with Saudi Vision 2030. Key launches included the Arizona series for rigid media, the Colorado M-series for high-volume roll-to-roll production, and the VP 6330 TITAN for superior book printing.

.jpg)

.jpeg)

.jpg)

.png)

.jpg)

_hw13rw8.jpeg)

Recent Comments