GulfPack Announces Major Expansion in BOPP Film Production

Gulf Packaging Industries Co. (GulfPack), a leading manufacturer of BOPP, CPP, and metallized films, has signed contracts for a significant expansion to enhance its production capacity and support the growing demand from customers worldwide.

As part of this expansion, GulfPack will install two new state-of-the-art 10.4-meter-wide BOPP production lines at a new facility, increasing its BOPP film capacity from 183,000 tons per annum (TPA) to approximately 318,000 TPA. The new lines are scheduled to commence production in 2026 and 2027, respectively.

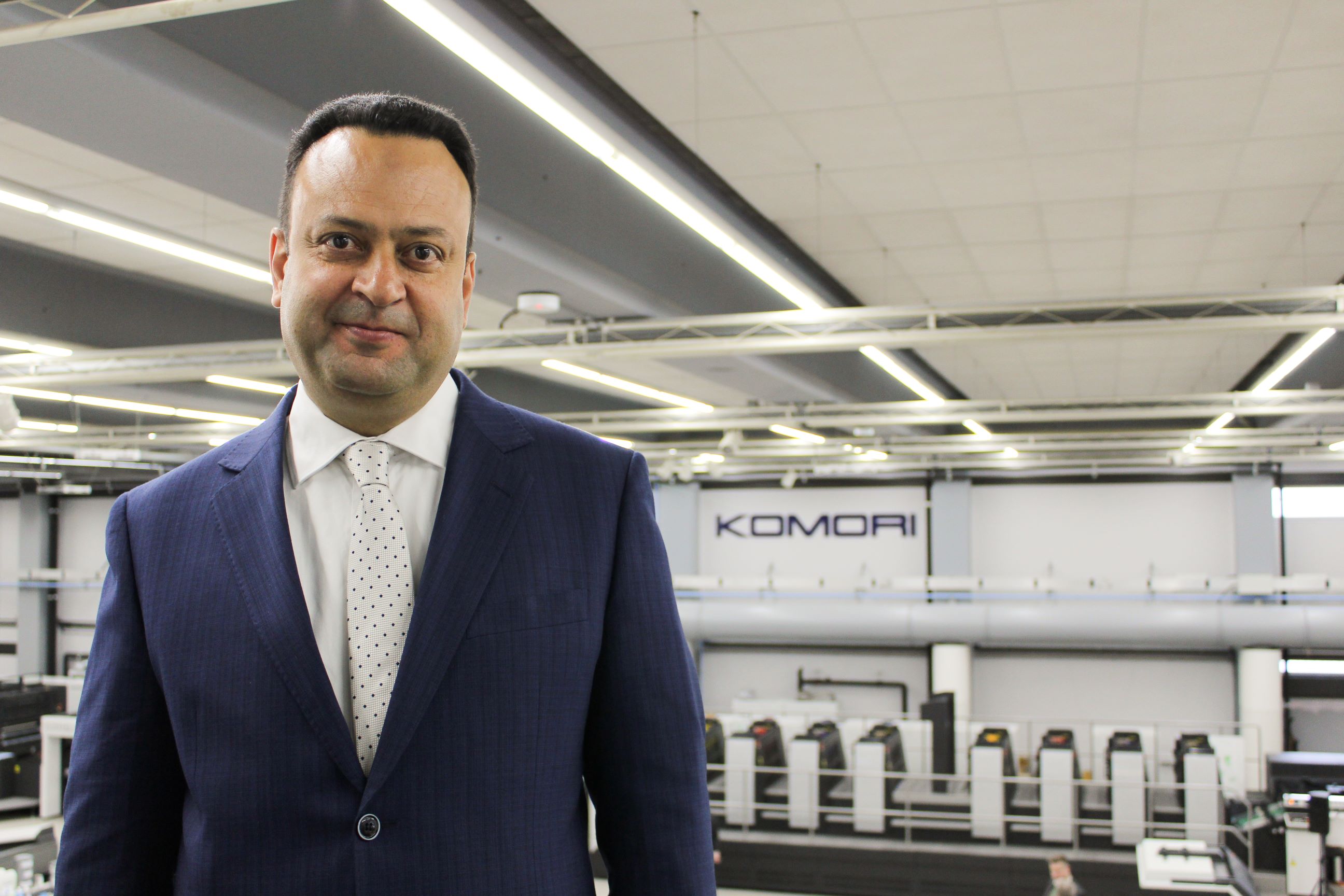

“This expansion is a testament to GulfPack’s unwavering commitment to innovation, sustainability, and customer service. We have received an overwhelming response to our recent expansions in 2023-24, and with our customer base growing rapidly, demand for our high-performance films continues to surge across the globe. Today, we export to over 75 countries, and these new investments will allow us to enhance our supply capabilities, strengthen partnerships, and support our customers in achieving their growth ambitions. With cutting-edge technology and an unwavering focus on developing mono-material sustainable solutions, we are driving the future of flexible packaging,” said Naif AlAnsari, CEO of GulfPack.

As a forward-thinking manufacturer, GulfPack is committed to driving sustainable innovation. These investments reinforce our commitment to developing solutions that support recyclable mono-material structures while reducing the environmental footprint of flexible packaging.

About Gulf Packaging Industries Co.

GulfPack is a leading manufacturer of BOPP, CPP, and metallized films, serving packaging converters and FMCG companies with innovative and sustainable packaging films globally. With headquarters in the Kingdom of Saudi Arabia, a sales and distribution hub in the USA, and sales offices in 10 locations globally, we proudly support clients across 75+ countries.

.jpg)

.jpeg)

.jpg)

.png)

.jpg)

_hw13rw8.jpeg)

Recent Comments