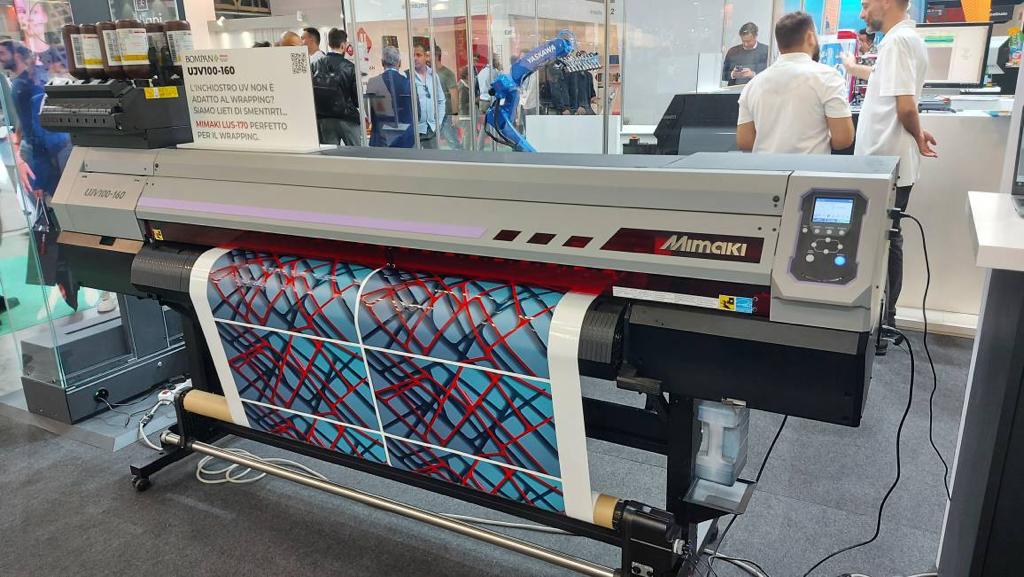

Mimaki launches two new textile printers

Mimaki’s distributor for the UK and Ireland, Hybrid Services, has revealed details of the manufacturer’s two new direct-to-textile printers, the Tx330-1800 and Tx330-1800B.

The new Tx330 Series printers are said to offer extensive textile printing capabilities and are able to print on a variety of materials with minimal wastewater.

In contrast to conventional textile printing processes that require pre- and post-processing equipment, the Tx330 Series printers are said to be more space-efficient and therefore suited to users with limited space.

The printers are equipped with dual inkset capability to easily switch between textile pigment inks and dye-sub inks.

Unlike conventional dye inks, these are said to simplify the process with a straightforward printing and heat fixation procedure. This eliminates the need for extensive facilities for water supply, drainage, and wastewater treatment, as well as the dyeing expertise needed to operate.

The Tx330-1800 can print on both fabric and paper, making it suitable for producing textile signage and interior fabrics.

The Tx330-1800B, meanwhile, uses a space-saving belt conveyor to stably print on stretchy, thick, and thin fabrics commonly used for apparel, making it suitable for smaller spaces like offices, schools, and retail stores.

Arjen Evertse, general manager sales EMEA at Mimaki Europe, said: “Looking at today’s textile market, we anticipate that the demand for textile products produced on-demand and locally will continue to grow.

“So, with that in mind, we released two products which are easy-to-use, versatile and sustainable, for those printers looking to incorporate textile printing capabilities within a small space, without compromising on capabilities and quality.

“The ink versatility aspect of these printers tackles the important concern of industrial water pollution, of which traditional textile dyeing alone contributes around 20% to.

“Utilising textile pigment and dye-sublimation processes, Mimaki’s latest printing solutions remove the need for the large amounts of water typically required in post-processing, creating a much more resource efficient process with almost no water used at all – while also significantly reducing energy consumption.”

The Tx330-1800 Series utilises Mimaki’s ‘330 Engine’ so provides the same sharp details, smooth colouring, and accurate colour printing as other machines in the 330 Series due to smooth gradation expression and high-density printing capabilities.

To accompany the new printers, Mimaki has also introduced TxLink5 textile RIP software. This is designed to further improve the workflow in environments with multiple printers, which is said to enable users to manage their printing processes more efficiently.

Fespa Global Print Expo, which will be held in Berlin from 6 to 9 May, will mark the EMEA debut of the Tx330-1800 and the unveiling of further details concerning both printers.

The new machines will then both be available for the textile and apparel market in June 2025. Pricing has not been disclosed.

.jpg)

.jpeg)

.jpg)

.png)

.jpg)

_hw13rw8.jpeg)

Recent Comments